– is a vertical machining center that is known for its high productivity and precision. Here are some of its key features:

This machine is suitable for machining various materials, including inconel and aluminum, and is ideal for automation and robotization

– is a high-performance horizontal lathe with a Y-axis that is designed for maximum productivity and accuracy. Here are some of its key features:

This machine is ideal for demanding machining tasks where high precision and reliability are required

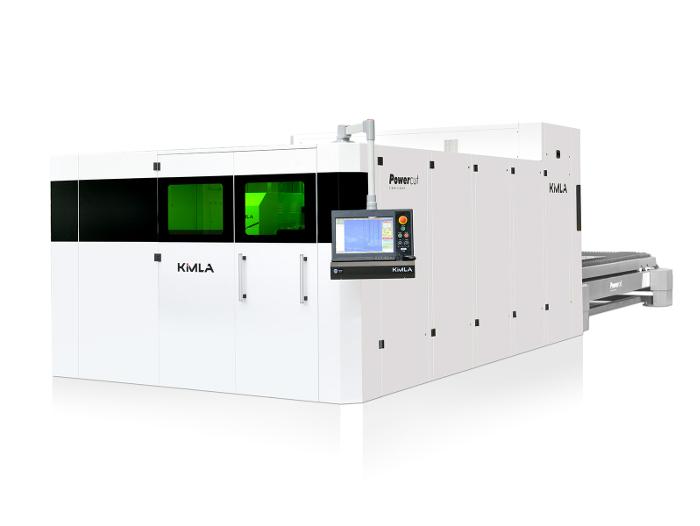

Laser cutters are designed for cutting flat metal materials with a laser based on a computer-generated tool path. The simple construction and use are also characterized by extraordinary reliability and durability.

Durma AD-Servo press machine is a CNC production equipment used for bending various types of sheet metal. Thanks to its compact yet robust construction, this machine is suitable for streamlining the owner’s production. Computer control of the machine ensures first-class accuracy and production efficiency.

threading capacity M3 – M27 (for soft materials up to M33)

The machine is made of two arms connected to each other in such a way that they form a pantographic system guaranteeing the perpendicularity of the tool to the clamping plane at every working point. The system is balanced by an air spring located in the arm body.

Potentiometers are placed on the motor and allow us to regulate the right and left revolutions of the tool and to regulate the dosage of tap lubrication.

Massive, fully equipped lathe with digital position measurement. Extremely quiet operation without vibrations is ensured by the stand and the bed, which are cast from one piece.

Arguments that will convince you about quality, performance and price

Professional column drill Opti B 40 GSM with a gear train, electromagnetic spindle feed switching, thread cycle, and cooling.

Semi-automatic hydraulically controlled two-column band saw.

The band saw is designed for both vertical and angled cutting in a semi-automatic cycle. It allows angled cuts to the left (60 degrees) and to the right (60 degrees). It is suitable for serial production and thanks to its robust construction, it enables the cutting of a wide range of materials, including stainless steels and tool steels, both profiles and whole materials.

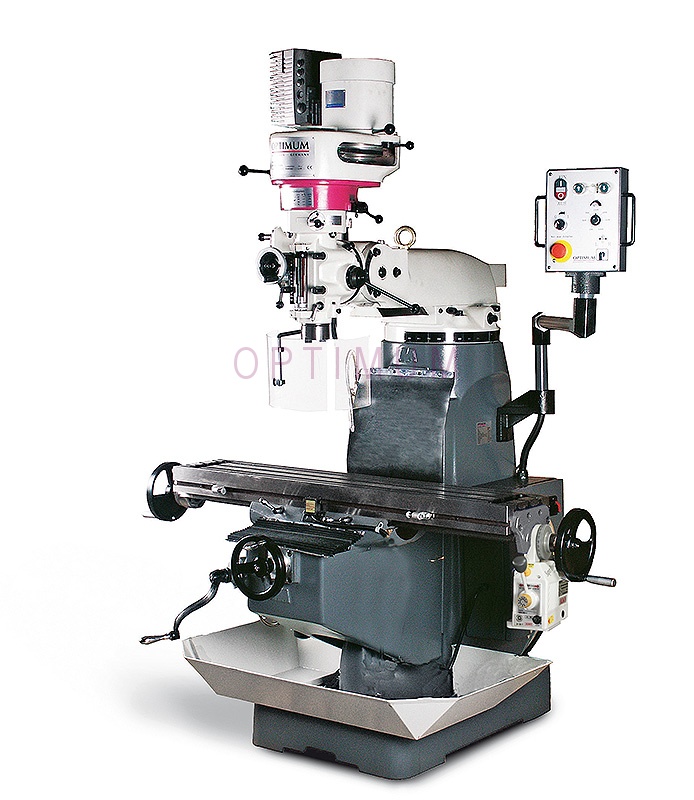

Universal drill-milling machine in massive design for professional use with frequency converter brand. Lenze “Made in Germany” with digital measurement of all axes (X, Y, Z).

Arguments that will convince you about quality, performance and price

Professional band saw for accurate and economical metal cutting with a rotating arm.

Distinctive features of the Opti S 300 DG Vario saw

This CNC milling center has a wide range of use thanks to a magazine for 24 tools as well as a work table size of 2m x 1m. The machine is equipped with modern clamping devices, so it is possible to process materials of various shapes. The control system is provided by Heidenhain, which is the world leader guaranteeing accuracy and maximum use of the machine within its capabilities.